Search

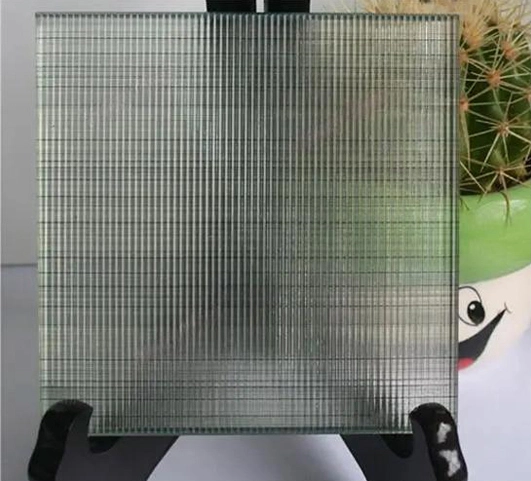

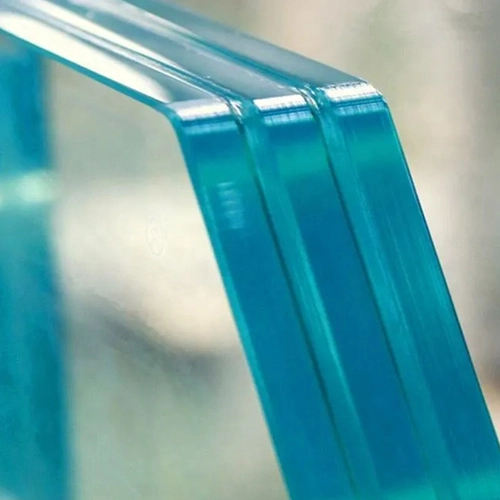

SGP is short for SentryGlas Plus, it’s from Dupont , it’s proved the most stiff and safest interlayer used in architectural glass.

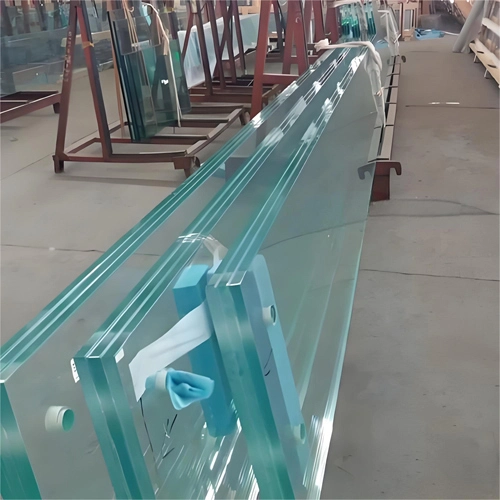

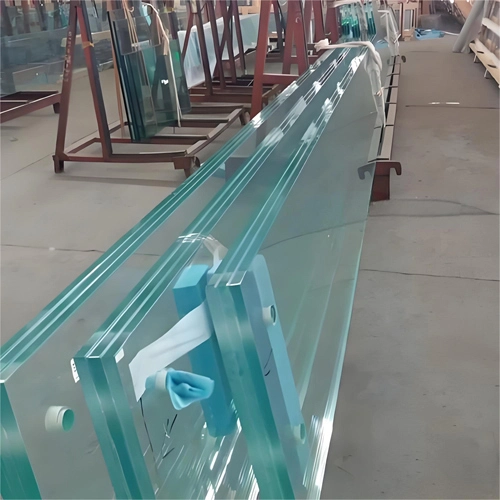

For glass bridges, glass canopy, glass walls , the SGP laminated glass is the best choice.

The only disadvantage of SGP laminated glass is the cost higher.

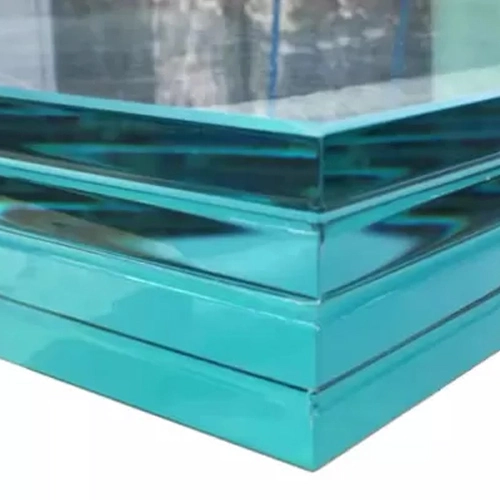

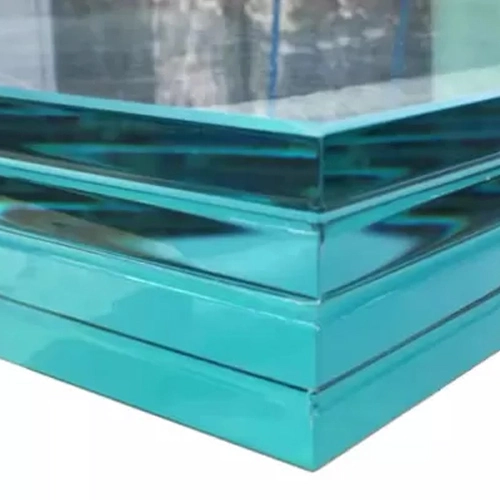

| Clear,Low Iorn,Tinted,Coated,Silk Screen Laminated Glass | |

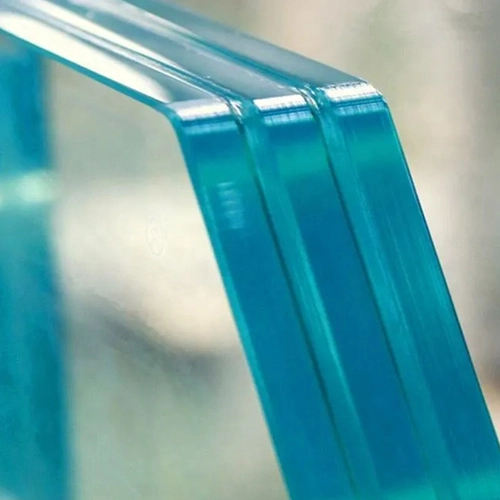

| Interlayer Types | PVB, SGP,EVA |

| Interlayer Thickness | PVB/EVA:0.38-3.04MM, SGP:0.76MM,0.89MM,1.52MM |

| Glass Standard | EN12150, ANSI2208,ASTM C1048,GBT15763.4,GBT15763.2GBT17841, 5 years warranty |

| Glass Size | MIN 300*300MM, MAX 13000*3000MM |

| Monthly Output | 20,000SQM |

Pls leave a message if you have any inquiries or questions, thank you.

Juyuan Road, Wangcun Town, Zibo City, Shandong Province, China

QUICK LINKS

Phone

+86-13505332015Address

Juyuan Road, Wangcun Town, Zibo City, Shandong Province, China