Screen printing refers to the use of screen printing plates, the use of glass printing materials on glass products for decorative printing technology. This is an important process for making decorative glass. Today, glass screen printing has the following eight processes.

The traditional etching decoration method of glass products is to heat apply a wax layer and other strengthening materials on the surface of the glass as an anti-corrosion layer, and then carve a pattern on the coating with a needle and a knife to expose the glass surface. This process is very time-consuming and labor-intensive and inefficient, but some manufacturers still use it today.

Today's glass etching screen printing process makes etching easier and easier, saving time and effort. There are two kinds of screen etching process:

(1) Hot printing. The hot printing method of glass screen etching is to make an anti-corrosion printing material by adding a small amount of anti-corrosion powder to the adhesive prepared by paraffin, asphalt, stearic acid, etc., through the hot screen plate, according to the design pattern, the printing material is scratched to the glass surface to form an anti-corrosion film. The part of the glass exposed on the resist film is the pattern that needs to be etched. The etching is carried out with chlorofluoric acid. After etching, the resistant layer printed on the glass is washed away with boiling water. Hot printing is suitable for etching of two continuous and four continuous patterns.

(2) Cold printing. Glass screen etching can also be carried out by cold printing method. Resist printing material can use special asphalt paint and resist powder, you can also buy commercially available resist inks. After printing, wait for the corrosion film to dry completely. Cold printing is suitable for etching individual patterns.

Ice flowers, commonly known as orange peel, are actually very fine, low-melting glass particles. This fine glass particles, high lead content, color and colorless two, color hue red, yellow, blue, green, white, etc., can also be prepared to the middle tone. Silkscreen ice flower decoration, simple and elegant, mostly used in architectural glass decoration and arts and crafts glass decoration, such as the decoration of high-grade glassware, lamps and so on.

Glass ice decoration silk screen printing method, is first on the glass surface of the colored or colorless glass flux layer (flux), and then the ice glass particles scattered on this layer of glass flux layer, through 500℃ - 590℃ sintering, so that the glass surface of the flux layer and ice grain layer co-melt and produce relief effect. If the silk screen on the glass is colored flux, and the micro ice flower is transparent, through high temperature eutectic, the flux layer of the glass ice pattern part fades, and the colored, raised transparent relief pattern is formed on the glass surface.

Coating is a decoration method that adheres to a certain size of glass glaze powder on the glass, and is baked at a high temperature of 580 ° C -- 600 ° C to melt the glass glaze coating on the glass surface and show a different color with the main body of the glass. Adhesive glass glaze powder, can be used to brush brush, also can be rolled by rubber roller.

Through the silk screen processing, the hollow pattern can be obtained. The method is to screen print a pattern formed by the dream yarn screen blocking agent on the surface of the glass product. Flux inhibitor, composed of iron oxide, talc powder, clay and other ingredients, grinding with a ball mill, fineness of 350 mesh (refers to a distance of one inch to 25.4 mm distance within 350 uniform size mesh), mixed with adhesive before screen printing.

After the printed pattern is dried, it is then processed with sand. Then after high temperature baking, the sanding surface without pattern will melt on the glass surface, and the place where the silk screen pattern is printed due to the action of the flux inhibitor, the sand surface covered in the pattern can not be melted on the glass surface. After baking, the transparent pattern of the floor is revealed through the translucent sand surface, forming a special decorative effect.

The principle of this method is that through the exchange of sodium ions in silver and glass, and then reduce it to become a metal glue, you can get colored glass. The screen ink containing silver ions is used to print only the part to be colored on the transparent glass plate, and after burning and washing, only the printing part is changed from yellow to brown. The silk screen printing ink of this decorative process is mostly composed of silver carbonate, copper sulfate (burnt powder), iron dioxide, talc powder, etc., with a small amount of zinc powder as a catalyst.

Different firing conditions will cause changes in tone and concentration. Since there is no reflection difference between the uncolored part and the colored part, there is no unnatural feeling at all, just like melting and coloring the glass. The coloring of the words and marks on the glass and the anti-heat treatment of the rear window glass of the automobile, as well as the brown color of the quantum scale used in the study experiment, are obtained by this method.

Switches combined with microcomputers are now used to design programs such as temperature regulation or switching for electrical appliances such as microwave ovens. This switch is different from the usual mechanical switch, is printed on the glass panel of the switch, there is no moving part, there is no convex and concave, very smooth, decontamination is easy, you can control the switch by hand touch.

The surface of the control panel is covered with a conductive film, and the ceramic ink is printed around it for decoration and text display. Its advantages are mechanical wear resistance, chemical corrosion resistance, easy decontamination. In addition, in order to color the glass, organic coatings can be printed on the back, because the back can not be directly contacted, strong durability, and the choice of ink is larger.

This method is the glass surface of the matting oil ink, with a screen plate printed on the sodium calcium glass, a few minutes after washing, the effect is like brown glass. Usually the use of fluoric acid for glass etching, there is a certain risk, with this ink does not contain strong acids, the operation is simple, its extinction effect and etching have the same wonderful.

In order to prevent the condensation of water vapor in the rear window of the car, the use of electric heating decontaminating lines is increasing. This method of silk screen printing is to apply silver paste into lines on smooth glass and fire the glass while bending it. When the rear window is fuzzy and fogged, the lines are heated by the current, raising the temperature of the glass surface and removing water vapor.

When this electric fog removal device is powered on, some cars do not use manual switches, but automatically power on and automatically power off. The sensor of this automatic device is a serrated electrode printed on a thin sheet glass, and then covered with a layer of humidity, using the change of humidity to automatically control power, power off.

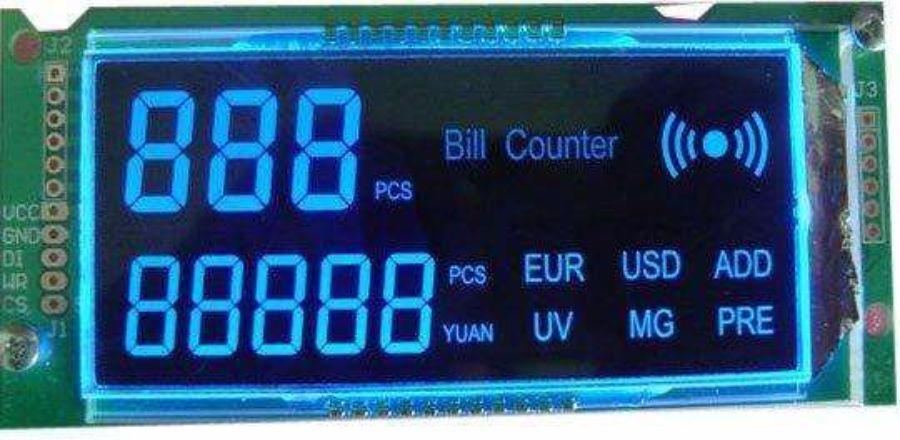

The liquid crystal digital display module is made by sealing the sides of two thin glass pieces about 10 microns apart, injecting the liquid crystal, and sealing the injection port. The silk screen printing method is on the surface of these two pieces of glass, the silk screen is a transparent electric conduction stock in the shape of "8", the "8" word is composed of 7 parts, and the voltage can be partially increased to display the corresponding number. The process of making this "8" font pattern is first to screen only the "8" font part on the glass with the entire electrical conduction strand, and then to etch with acid to remove the conduction strand of the unprinted part.

This is the last one.