Laminated glass production process: This process is used to produce high-performance safety glass composed of two or more pieces of glass and special glue or film. Laminated glass production method: There are two main methods, respectively, film hot pressing method and grouting method. Film hot pressing method: Most of this method uses silicone rubber ring, also known as silicon ring method.

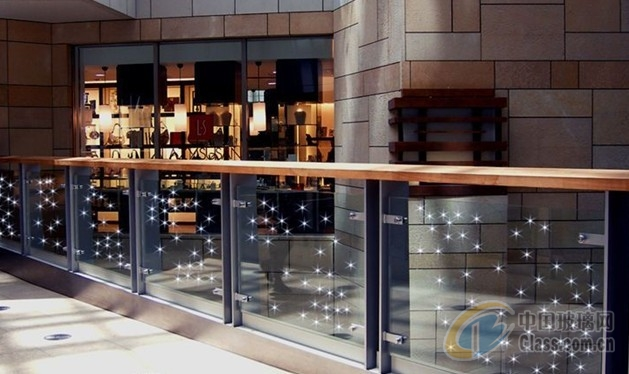

The color of laminated glass is generally white, which is a relatively safe glass. Now many building Windows will choose laminated glass production. Let's take a look at the production process of laminated glass. LED Glass, also known as photoelectric glass, Power Glass, is a perfect combination of LED light source and glass products, and break through the traditional concept of architectural decoration materials.

wet laminated: glue strips are pasted on the four sides of the glass, glue is injected, and the cured glass is laminated glass;

Dry glue: glass made by pasting film directly between two pieces of glass; Wet laminated glass is composed of two or more pieces of glass sandwiczed with polyvinyl butyral (commonly known as PVB) film.

There are obvious differences in production process and performance between dry and wet adhesive.

The dry method is to insert the film between two layers of glass, and then use the method of high temperature and high pressure to discharge the air in the film, so that the glass and the film are closely fitted. This method has the advantages of simple production process and high production efficiency, but it is easy to produce bubbles and impurities, affecting the transparency and strength of the glass.

The process of laminated glass is to put several pieces of glass and grinding pieces into a high temperature furnace, and press these materials into a piece of glass with high temperature and high pressure. From the production process point of view, there is a layer of damping sound insulation film in the middle of the laminated glass, so the sound insulation effect of the laminated glass is very good. Moreover, the safety of laminated glass is also higher than that of ordinary glass, and it will not break easily.

Because the wet method is formed by sunlight polymerization, that is, when processing and making, it is also necessary to choose the production in good weather, which can also reduce the bubble rate. The process is as follows: Cleaning: Scrub clean with acetone and dry. Edge: Insert the PVB film strip soaked by glue into the surrounding of the upper and lower two pieces of glass to form a cavity and clamp it with a clamp. Reserve a glue-filling opening for glue-filling when surrounding the edge.

1, Laminated glass production process introduction: This process is used to produce high-performance safety glass composed of two or more pieces of glass and special glue or film. Laminated glass production method: There are two main methods, respectively, film hot pressing method and grouting method. Film hot pressing method: Most of this method uses silicone rubber ring, also known as silicon ring method.

2, Laminated glass production process is a production of two or more pieces of glass and special glue or film combination of excellent performance of the safety glass process, the specific method has two kinds: film hot pressing method: film hot pressing method to achieve most of the silicone rubber ring, referred to as silicon ring method.

3, The production process of laminated glass has a total of two kinds: wet glue: glue strips on the four sides of the glass, filled with glue, curing is laminated glass; Dry glue: glass made by pasting film directly between two pieces of glass; Wet laminated glass is composed of two or more pieces of glass sandwiczed with polyvinyl butyral (commonly known as PVB) film.

4, Dry glue Dry glue in the process is to first clip a layer of PVB film between the two pieces of glass, clamp around, and then sent to the autoclave for high temperature and high pressure treatment, so that the PVB film between the two pieces of glass under the action of high temperature and high pressure will glue the two pieces of glass together. Generally speaking, the dry method is relatively simple and easy to operate, but the product stability is often not high, so the industry often uses wet method.

It is not possible to glue first, because the clamping process is very important and is a guarantee of safety performance. If the edge grinding after the glue is added, the adhesive layer will be destroyed, and the peripheral stress formed during the baking and bending process will be destroyed. The stress and the sandwich layer are destroyed, then the safety of the glue is meaningless.

Tempering edge grinding, because if not grinding, there may be small stubble on the glass edge, easy to break the wind, and the glass top is placed under the glue, so it is safer.

There is a splint on the edging machine, which needs to grip the glass to move forward, so that the glass will not be distorted when grinding the edge, and the size will be accurate. The splint is flat, all only suitable for grinding flat glass, the hot bend is arc, a splint is cracked. If you use a special-shaped edging machine, you can grind it, but the glass is curved, and the suction cup on the special-shaped machine cannot be sucked, and someone needs to hold the glass and grind it again.

1, Hollow laminated glass is a part of hollow glass, this kind of glass will be used in many buildings, its excellent physical properties, very suitable for installation and use in many medium and large occasions, the radiation resistance effect is also very good, but also has good thermal insulation performance, for heat obstruction effect is very good, but the production process is relatively complex.

2, Hollow laminated glass is integrated sound insulation anti-condensation and safety as one of the glass.

3, hollow laminated glass is a special kind of glass products, it combines the characteristics of insulating glass and laminated glass, the formation of both thermal insulation, thermal insulation properties, but also with safety, explosion-proof characteristics of composite glass. In detail, the structure of hollow laminated glass is usually composed of two or more pieces of glass bonded together through a laminated layer, and one or more sealed hollow cavities are formed between these glass pieces.

4, the difference between hollow laminated glass and insulating glass mainly lies in their structure and performance characteristics. First of all, from the structural point of view, insulating glass is composed of two or more pieces of glass through aluminum bars, sealant and other materials separated by a certain width of the air layer, the formation of multi-layer glass products. Hollow laminated glass is on the basis of hollow glass, adding a laminated layer.

5, the advantages and disadvantages of laminated glass and insulating glass advantages of laminated glass: sound insulation performance is better, but also to weaken the sun's radiation, after the glass is broken, the debris will not be scattered to the ground, but will stick together with the surface film. Disadvantages: water seepage is easy to occur, and the surface is easy to fog. Advantages of insulating glass: The performance of heat insulation and heat preservation is better, and the sound insulation effect is better than that of ordinary Windows.

6, What is insulating glass? Insulating glass, also known as sound insulation glass, was invented by the Americans in 1865. This glass is composed of two or three pieces of glass, between the use of high strength, high air tightness of the composite binder bonding, and built-in desiccant aluminum alloy frame, so that it has excellent thermal insulation, sound insulation performance, while having beautiful and practical characteristics, and can effectively reduce the building's weight.