According to the fireproof glass standard, fire-resistant glass can be divided into two types based on its fire resistance performance: Class A (Heat insulated fire-resistant glass) and Class C (non heat insulated fire-resistant glass). In fact, the main difference between Class A and Class C fire-resistant glass lies in whether it is thermal insulated. Simply knowing the insulation properties of fire-resistant glass cannot fully determine its type.

Heat insulated fire-resistant glass, represented by FFB according to standards, means that the category of heat insulated fire-resistant glass sold in the market must be indicated on the product. For heat-insulating fire-resistant glass, it can also be divided into Class A and Class B. The thickness range of insulated fireproof glass is 5-35 millimeters. The commonly used thicknesses for Class A insulated fire-resistant glass are 30mm and 35mm; Class B insulated fire-resistant glass is 26 millimeters. Insulated fireproof glass can be customized in large sizes of 1500 * 2000mm.

In the FB-26-A1.00 composite insulated fire-resistant glass, A1.00, It refers to heat-insulating fire-resistant glass that can withstand fire for 1.0 hour; FFB refers to heat-insulating and fire-resistant glass, and 26 represents the thickness of the fire-resistant glass which is 26mm. Heat Insulated fire-resistant glass can be made using fire-resistant liquid or nano fire-resistant adhesive, and there are differences between the two.

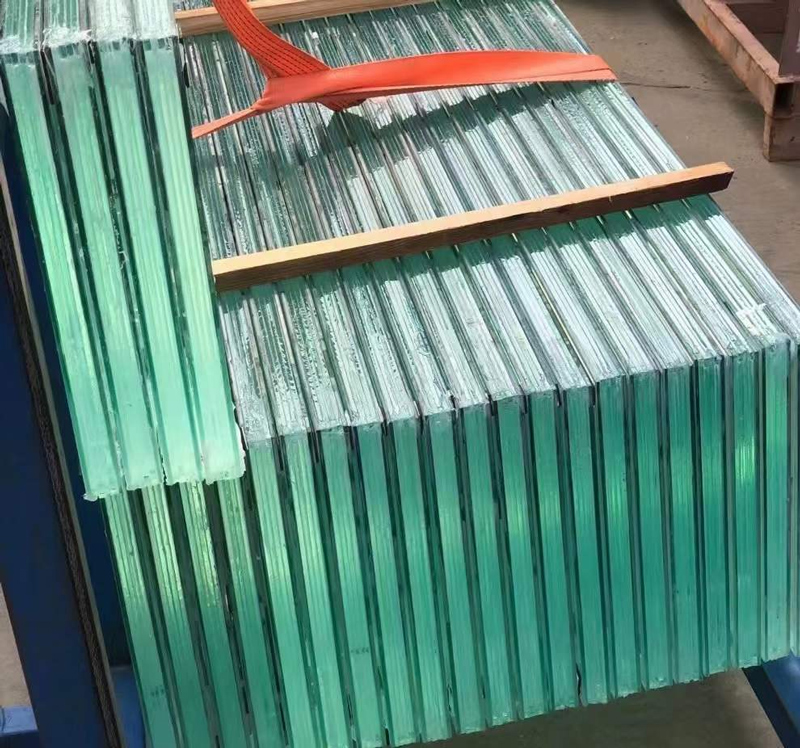

A、 Grouting fireproof glass: using a combination of fireproof liquid and fireproof glass. The key part of this method lies in the quality of the fire-resistant liquid. During the processing, the fireproof liquid is in a viscous liquid state. The edge is poured into the middle of two or more layers, sealed with glue, and then solidified and formed by physical air drying to complete the processing. If there are bubbles inside the glass after air drying, it is an unqualified product.

B、 Nano silicon fireproof glass: a multi-layer combination of fireproof silicon (adhesive) and glass. This method adopts dry processing and only requires high-temperature compression molding of multiple materials. Fireproof silicon is a newly developed variety. Although it has excellent fire resistance, due to its high production cost, only some large domestic manufacturers are producing it.

Grouting fireproof glass is made of fireproof liquid. Due to the characteristics of the product itself, it cannot withstand long-term ultraviolet radiation, otherwise it is prone to yellowing, foaming, and even leakage. Its weather resistance is poor and cannot be used outdoors for a long time. The nano silicon fireproof adhesive used in nano silicon fireproof glass is hard, physically and chemically stable, and has strong weather resistance.

Therefore, when choosing fire-resistant glass, it is necessary to consider multiple factors such as cost, effectiveness, and lifespan in order to select products that are suitable for the project.