Preface

The main reason for the self explosion of tempered glass is caused by nickel sulfide (Ni s) stones mixed in the float glass body. In order to reduce the probability of self explosion of tempered glass, some factories have adopted effective detection methods and treatment processes to reduce the self explosion of tempered glass.

EN 14179: 2005 standard is also dedicated to reducing the self explosion of tempered glass, with strong practicality. It not only shortens the processing time, but also effectively reduces the possibility of self explosion caused by nickel sulfide, verifying its feasibility for damage testing.

The main method is to heat soak the tempered glass to reduce local stress concentration caused by stones, thereby reducing the harm of tempered glass during use.

Heat soaked treatment

Glass deep processing enterprises adding heat soaked treatment technology after completing glass tempering treatment can effectively reduce the probability of self explosion of tempered glass.

The heat soaked furnace is as below:

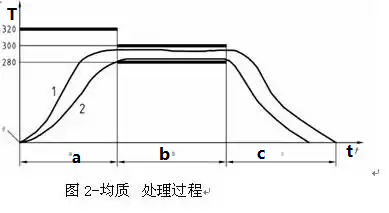

The heat soaked processing includes three stages: heating, constant temperature, and cooling, as shown in below. Among them, a is the heating stage, b is the constant temperature stage, C is the cooling stage, T is the temperature of the glass, T is the processing time.

* 1 Heating Stage

The heating stage begins after all the glasses are loaded into the homogenization furnace and ends when the last piece of glass reaches 280 ℃. The time to reach this temperature is determined in the calibration program. This time depends on the size of the homogenization furnace, the amount of glass processed, the spacing between the glasses, and the heating capacity of the heating system. It should be noted that the spacing and heating rate of the glass should be controlled to minimize the breakage of the glass due to thermal stress.

To promote effective heating, the air temperature inside the furnace can reach 320 ℃. However, the instantaneous temperature on the surface of the glass should not exceed 300 ℃ to prevent stress relaxation in tempered glass.

* 2 Constant Temperature Stage

The constant temperature stage begins when the surface temperature of all glass reaches 280 ℃. The duration is 2 hours. The temperature control range during the constant temperature stage is 290 ± 10 ℃, in order to ensure that the surface temperature of the glass remains constant throughout the entire constant temperature stage

To maintain within the specified range, the homogenization furnace requires precise control.

* 3 Cooling Stage

After the constant temperature is reached, the glass begins to cool down. At this stage, the glass temperature should be cooled to ambient temperature or stopped when the air temperature inside the furnace reaches 70 ℃. The cooling rate should be controlled to minimize the breakage of glass due to thermal stress.

* 4 Heat Soaked Processing system

(1) Heat Soaked furnace

The heat soaked furnace should use convection heating to evenly heat each piece of glass through air circulation. If there is glass damage, the airflow must not be obstructed. The airflow inside the furnace should be parallel to the surface of the glass. The design of air inlet and outlet should ensure that glass fragments do not block it.

(2) Glass placement

Glass is best placed vertically. Cannot be completely fixed, it should be ensured that it can expand freely. Glass spacing can affect gas flow rate, heat exchange, and heating time, and glass should not come into contact with each other.

(3) The Space Between Each Pc of The Glass

Glass should be separated in a way that does not affect the flow of air. Spacers should not obstruct airflow, and it is recommended to have a glass spacing of 20mm.

Conclusion

The main reason for self explosion caused by nickel sulfide in tempered glass depends on the phase transition of tensile stress caused by environmental temperature. In order to reduce and prevent self explosion caused by nickel sulfide in tempered glass, heat soaked treatment is carried out in the factory of deep processing enterprises to reduce the probability of self explosion. Recent studies have shown that not all self explosions of tempered glass come from nickel sulfide stones, and nickel sulfide is only one of the reasons for self explosions of tempered glass. In order to achieve better development of the glass industry, it is more worthwhile to have a deeper understanding of the self explosion of tempered glass in the future.