Search

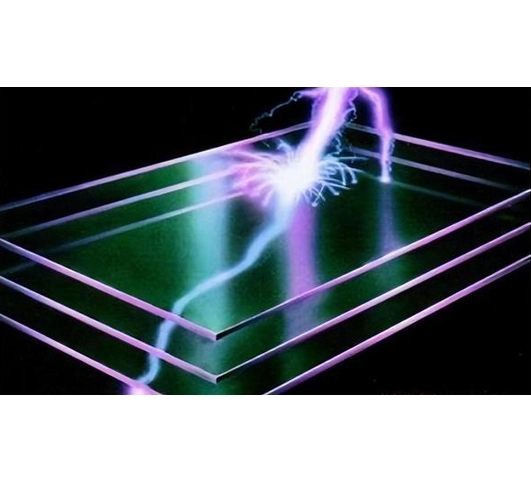

It’s to simulate the impact force in a real environment to test the impact resistance of laminated glass. The tools contain the mpact device and the 45-46KG ball ,the ball biggest diameter is 250mm, filled with small lead balls.

The size of glass normally is 1930x864mm.

The procedure is as below:

1, Place the glass in the frame and tighten it

2, Adjust the height of the impact ball to 300 mm – mark C on the rod.

3, Once the ball stabilized release the rope and let the ball to move freely toward the glass.

4, Check the results.

5, After the release of the ball, it’s acceptable that there appear many cracks and splits on the glass but it’s rejected if there is a hole or a rip that will allow a 76 mm diameter ball to freely to though the glass.

6, If after 3 minutes from the impact test some fragments and particles got disconnected from the glass – this total weight should not be higher than the weight of 10,000 Square millimeters of the original sample.

7,The weight of one of the biggest fragments should not be higher than the weight of 4400 square millimeter of the original sample.

8, NOTE: if all the above were confirmed the glass can pass the test

9,Proceed with the height of 750mm and 1200mm.

10,The test needs to be documented and recorded.

QUICK LINKS

Phone

+86-13505332015Address

Juyuan Road, Wangcun Town, Zibo City, Shandong Province, China