Search

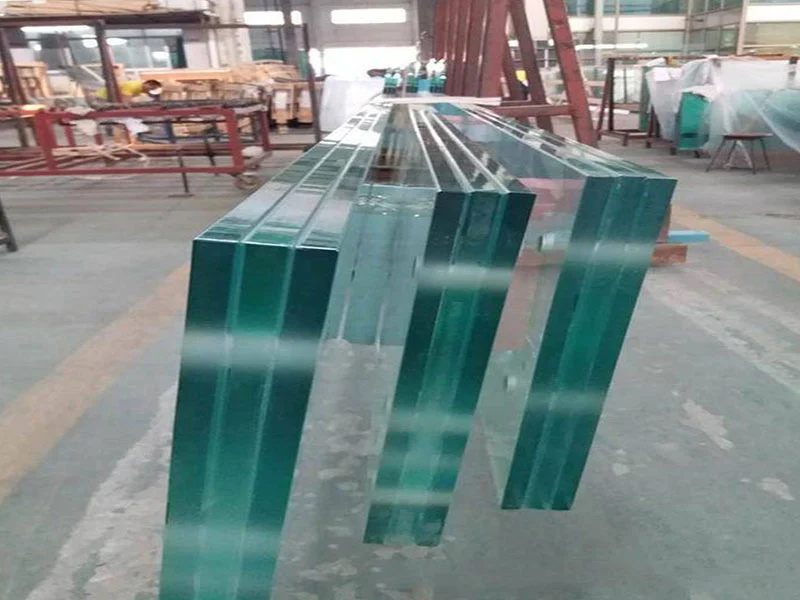

Boiling test is to simulate the extreme conditions such as high temperature and humid environments. By boiling laminated glass samples in boiling water for 2 hours, the stability and durability at high temperatures can be evaluated.

Boiling test can also verify the water resistance and stability of the adhesive layer of laminated glass. During the boiling process, if the adhesive layer of laminated glass peels, bubbles, or leaks, it indicates poor water resistance and adhesive stability, and may not be able to maintain long-term stability and safety in actual use.

Lanjing do the test for each laminated glass order before starting the whole order processing.

The procedure of boiling test:

1. Samples need to be placed in bath #1 in which water temperature should be 65˚.6 C (±2.8 ˚ C) for 3 minutes. Take out and place in Bath #2 immediately.

2. Samples should be placed in bath #2 with boiling water for two hours. As soon as 2 hours pass – take the samples out.

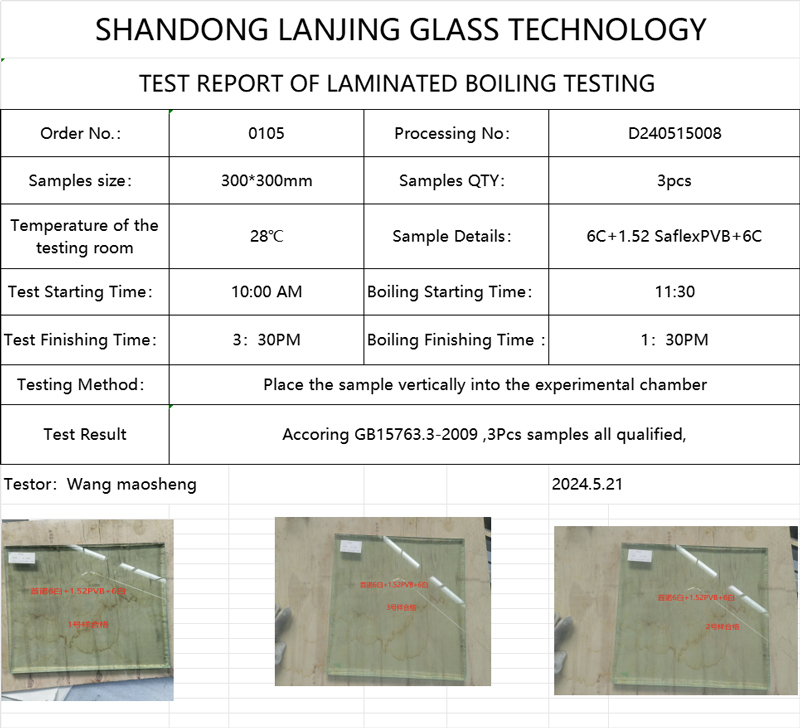

Result:

It is acceptable if a sample appears crack during the test but, if the crack was too big that the test performer cannot have any conclusions – the sample should be disqualified and replaced.

Good result of the test is when there won’t be any bubbles or other defects in 13 mm distance and higher from the edge of the glass or from any crack that appeared.

Record

Record each test result

QUICK LINKS

Phone

+86-13505332015Address

Juyuan Road, Wangcun Town, Zibo City, Shandong Province, China