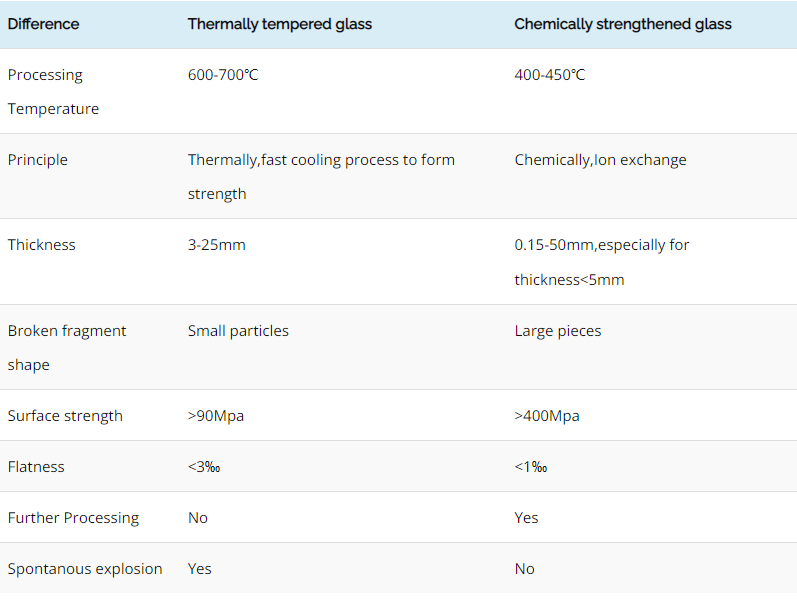

In the construction industry, glass is used more and more widely. Compared with traditional building materials, it is not only beautiful, but also energy efficient. However, glass is a very fragile product, and many people will worry that its high breakage rate will inconvenience people. In fact, a long time ago, people recognized this problem, so wise people have developed the process of strengthening glass, through a variety of strengthening processes, can make the glass stronger. The main methods to improve the strength of glass are Thermally tempered glass and Chemically tempered glass. what's the difference between the them?

Thermally tempered glass: The principle is to heat the glass to the appropriate temperature (670-720 ° C), and then cool it quickly, which will cause the glass surface to shrink sharply and form compressive stress. However, the middle area of the glass cools more slowly, forming tensile stress and making the glass obtain higher strength. Normally, the higher the cooling strength, the stronger the glass.

Chemically strengthened glass: the glass is immersed in the alkali salt solution at 400 ° C, so that the ions with small radius of the glass surface and the ions with large radius of the solution can chemically exchange.

For example, lithium ions in glass exchange with potassium ions or sodium ions in solution, and sodium ions in glass exchange with potassium ions in solution. The difference in the volume of alkali ions is used to create intercalation stress on the glass surface. The number of large ions squeezed into the glass surface is proportional to the surface pressure, so the amount and depth of ion exchange determines the final strengthening properties.

Advantage and disadvantage of Thermally tempered glass:

Advantage 1: Low costs and high efficiency. Thermally Tempered can be finished within 10 minutes.

Advantage 2: High mechanical strength, thermal resistance (safe working temperature can reach 287.78℃).

Advantage 3:Safety, if glass broken,it will break into small fragments, that can reduce harm to the human body.

Disadvantage 1 :Glass self explosion.Tempered glass can explode during tempering processing, storage, transportation, installation, and even after installation in uncertain time.

Disadvantage 2: Tempered glass cannot be further processed- so glass must be cut and polished before tempering process.

Advantage and Disadvantage of Chemically strengthened glass:

Advantage 1. High strength, uniform stress, good stability, no self-explosion phenomenon, can be further cut and processed, no deform, no optical distortion, and is suitable for the reinforcement of glass products with special shapes and thin glass panel.

Advantage 2. The strength is 5 to 10 times that of float glass, the bending strength is 3 to 5 times higher, as well as 5-10 times higher impact strength. It improves the strength and safety at the same time. Chemical strengthened glass has higher strength than thermally tempered glass based on same thickness.

Advantage 3. The resistance to rapid cold and rapid heat is 2-3 times the normal glass, can withstand temperature changes of more than 150LC, No fragile, and no spontaneous breakage.

Advantage 4. No deformation, and can chemically strengthening any shape glass, Such as arc shape, cylindrical shape, bottle shape, box shape, flat shape etc.

Advantage 5. Suitable for ultra-thin products below 3mm,no optical deformation,no bending.

Disadvantage : High production costs, low production efficiency.

Thermally tempered glass:Widely used in places with high mechanical strength and safety requirements, such as: curtain walls, facade windows, indoor partitions, furniture, household appliances, partitions near heat sources and locations subject to severe cold and heat shocks, etc.The tempered glass will always been further processed to be laminated ,double glass units to get better thermal,safety and acoustic performance.

Chemically strengthened glass:Usually used in electronic display products, such as monitors, televisions, tablets, mobile phones, etc. as screen protection panels.

Meanwhile chemically strengthened glass are used for architectural glass which cannot be toughened by glass tempering furnace,such as hot bending glass,irregular shape glass etc,as well as some area require extreme high strength glass such as high speed train.