As we all know, insulating glass in addition to air, argon is also a common choice. Argon filling and the use of warm edge gaskets can reduce the glass U-value by 0.2-0.3w/m2.k. In addition, the benefits of argon filling are:

Improved acoustic performance.

Keep the air pressure balanced inside and outside the glass.

Increase glass wind resistance and glass strength.

Prolong the service life of aluminum spacer molecular sieve

Customers can get positive feedback for as little as $1.50 / m2. I BS en1279 - insulating glass standards require that the argon content should not be less than 90% and no leakage, and some glass manufacturers do not have the correct operating rules during the filling process, and lack the necessary tools to measure and test the argon content, which leads to the poor quality of the double-layer glass units made in China, the argon content is far from meeting the requirements. Resulting in an increase in overall building energy costs.

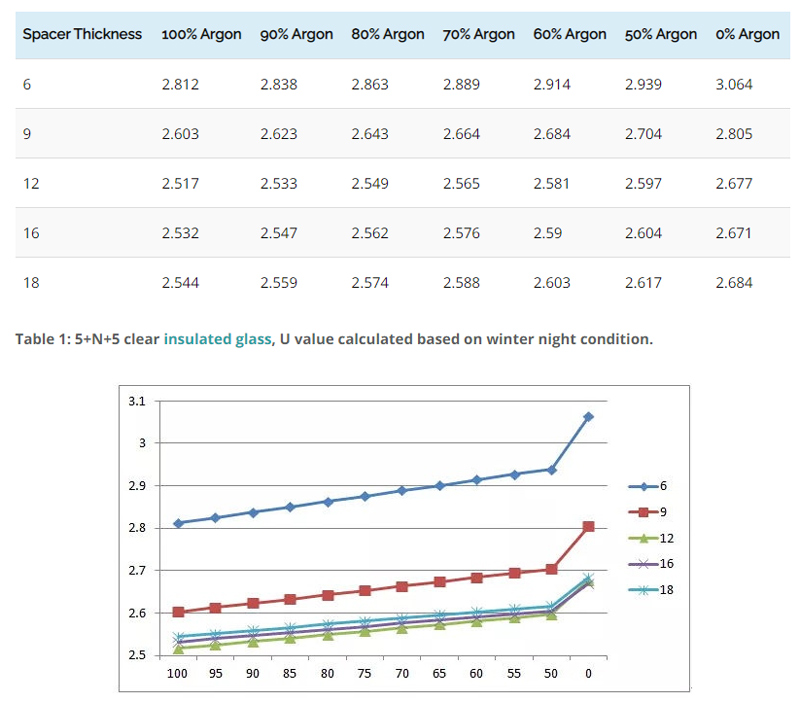

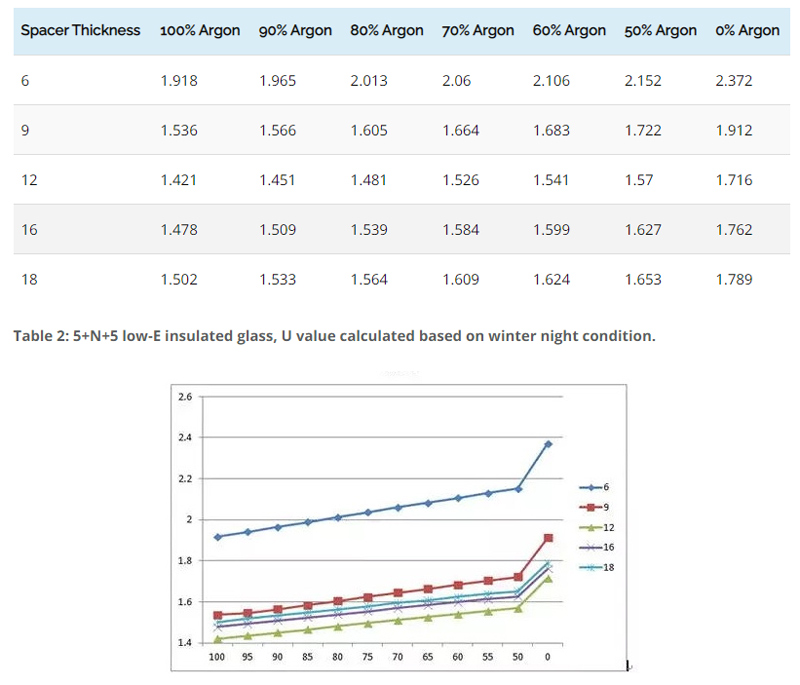

Why is argon content so important? How does argon content affect the properties of glass? Here we use Window Therm to calculate the properties of the glass to check how it works.

90% content U value is 0.226W/m2.k than 0% content for 5+9A+5.

90% argon content is 0.081W/m2.k than 50% content for 5+9A+5.

90% content U value is 0.346W/m2.k than 0% content for 5LE+9A+5.

90% argon content is 0.156W/m2.k than 50% content for 5LE+9A+5.

CONCLUSION:

The argon concentration has a great influence on the heat transfer coefficient of insulating glass, especially for Low-E insulating glass. For Low-E insulating glass with different spacing thicknesses, the central heat transfer coefficient is improved by an average of about 0.3 W/(m²·K)

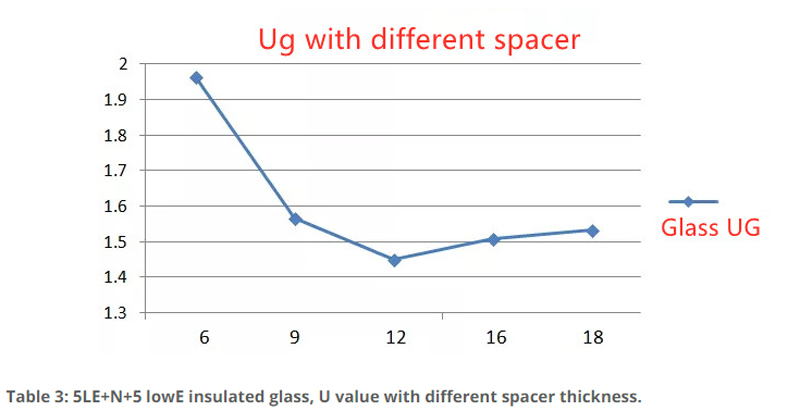

When the glass thickness and argon gas concentration remain unchanged, with increased spacer thickness, the heat transfer coefficient shows a trend of “decrease first and then increase”. The ideal thickness is approximately 12 mm. After reaching 12mm, the convection of enclosed air or argon increases, increasing the convective heat transfer, resulting in the heat transfer coefficient of the insulating glass decreasing first and then increase.

But if applied in aluminium windows,we can get below conclusion:

When the argon concentration drops by 10%, the U value (Ug1) in the center of the insulating glass will increase by about 0.03 W/(m²·K), and the heat transfer coefficient (Uw) of the entire window will increase by about 0.02W/(m²·K).

To ensure the IGU used in your curtain wall,you must work with premium glass suppliers with guaranteed quality with over 90% argon content. Do work with glass processors with EN1279, and IGCC certificate,Lanjing would like to offer more measurements- warm edge spacer,superspacer,high performance world class coating,triple glass units etc to save more energy furthermore.

How we ensure the argon content:

Advanced insulating line with online argon filling function.

Complete argon content detect for every piece.

EN1279/ IGCC certificates.