Search

There are many insulated glass filled in argon gas, why this needed?

The main reasons for filling insulated glass with argon gas include the following aspects:

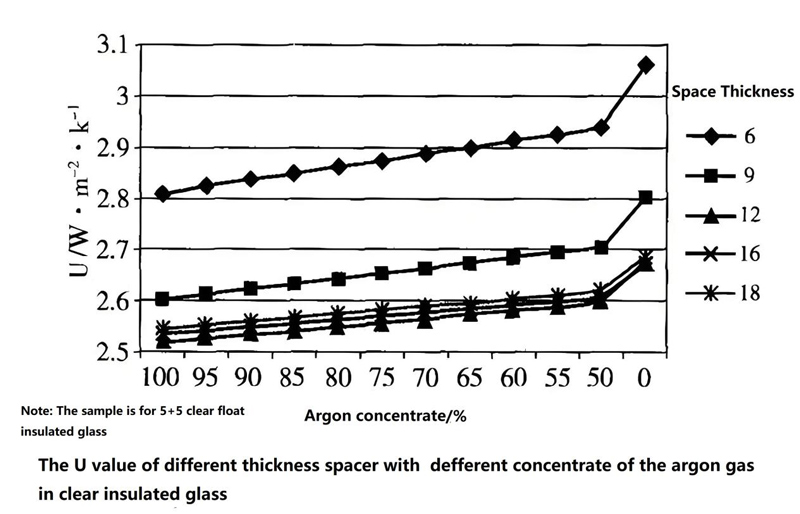

Thermal insulation and heat preservation:

Argon gas is an inert gas with poor thermal conductivity. When filled into insulating glass, it can reduce the heat transfer coefficient and decrease the heat exchange between indoor and outdoor environments, thus achieving the effect of thermal insulation and heat preservation.

Sound insulation: Argon gas can reduce the resonance effect of sound and effectively isolate outdoor noise, especially high-frequency noise such as human and car sounds. Insulated glass filled with argon gas has about 30% better sound insulation effect than unfilled glass.

Preventing fogging

Injecting argon gas can expel air containing water vapor, avoiding fogging of insulating glass and maintaining its clarity.

Reduce self explosion rate

Argon gas can effectively reduce the heat transfer efficiency of doors and windows, decrease the frequency of thermal expansion and contraction, and thus reduce the risk of glass self explosion.

Enhance glass strength

The density of argon gas is greater than that of air, and filling it in insulating glass can resist air pressure, avoid glass suction, and improve the wind pressure resistance of glass.

Extended the lifespan

Filling with argon gas can keep the glass environment dry, reduce the oxidation rate of aluminum bars, and extend the service life of aluminum bars and molecular sieves.

The process of filling argon gas usually includes triple sealing and double-layer anti fog steps to ensure that the gas does not leak and to keep the inside of the glass dry and clear.

QUICK LINKS

Phone

+86-13505332015Address

Juyuan Road, Wangcun Town, Zibo City, Shandong Province, China