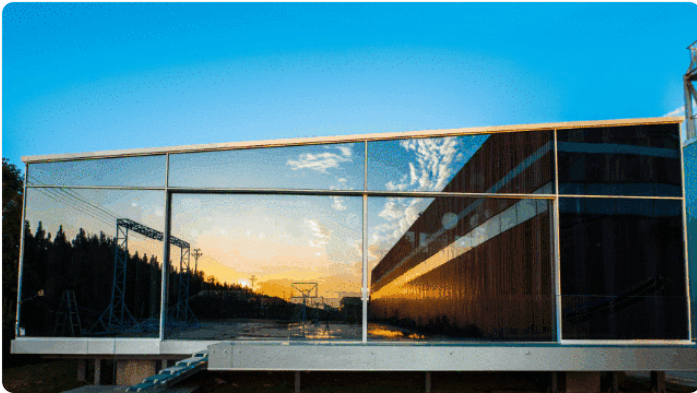

Tempering furnace is a key equipment for tempered glass production, and any operation may ultimately affect the quality of tempered glass. LANJING TEMPERING FURNACE

Today we will talk about the factors that affect the degree of glass tempering and how to make tempered glass more durable.

Firstly, the temperature control of the tempering furnace

The tempering temperature of a tem.pering furnace has a crucial impact on glass. Appropriate temperature can maintain a certain stress difference between the inside and outside of the glass, thereby evenly heating it, enhancing its strength and wear resistance, and improving its impact resistance.

Excessive or insufficient temperature can affect the tempering effect of glass, and in severe cases, even lead to deformation and cracking.

Secondly is the cooling rate.

Rapid cooling can increase the surface tension of glass, making it stronger and harder.

By controlling the cooling rate of the tempering furnace, we can better ensure uniform cooling of the glass surface and interior, without causing quality problems with tempered glass due to too fast or too slow cooling rates, making it difficult to achieve the desired tempering effect.

The third is the quality of the glass itself.

Glass of different materials and compositions has different temperatures and times during tempering. Therefore, we should try to choose higher quality glass raw materials, keep them clean and smooth, and make them more uniform and stable.

When necessary, an appropriate amount of sodium oxide, potassium oxide, etc. can be added to improve the performance of the glass, thereby achieving a better tempered glass effect.

The fourth is glass surface treatment. Smooth and clean glass raw sheets are the prerequisite and foundation for ensuring the quality of tempered glass.

When pre-processing the original film, it is necessary to do a good job of grinding, polishing, cleaning, etc., and deal with surface defects and scratches, otherwise it will affect the quality of the final tempered glass.

In addition to these, the experience and operational level of the operators, the material of the tempering furnace, the thickness of the glass, and so on, will all determine the final tempering effect. Only by accurately handling every detail of glass tempering can we better ensure the quality of the final tempered glass.

Firstly, in the production process, we should try our best to choose high-quality glass raw materials, improve the production process and technical level of glass tempering furnaces, accurately control every link in the production of tempering furnaces, and ensure the quality of tempered glass layer by layer. This fundamentally improves the durability of tempered glass.

Secondly, during use, we need to regularly inspect, maintain and upkeep, and promptly deal with any problems found to avoid more serious consequences. At the same time, try to avoid contact between tempered glass and strong acidic and alkaline substances, and avoid scratching with sharp objects.