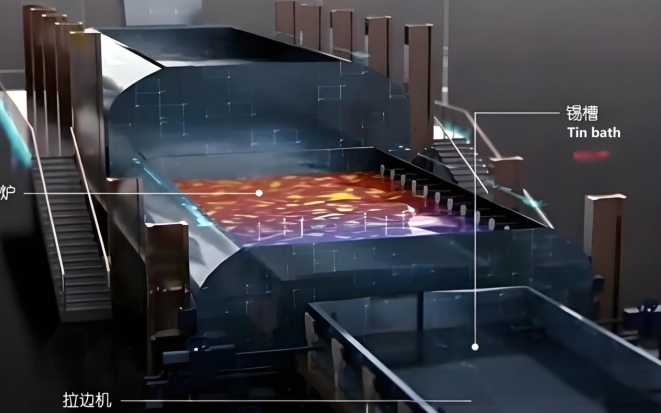

The forming process of float glass production is completed in a tin bath filled with protective gases (N2 and H2). Molten glass flows continuously from the tank furnace and floats on the surface of the relatively dense tin liquid. Under the action of gravity and surface tension, the glass liquid spreads and flattens on the tin liquid surface, forming a smooth upper and lower surface. After hardening and cooling, it is led up to the transition roller platform. The rollers on the roller table rotate, pulling the glass ribbon out of the tin bath and into the annealing kiln. After annealing and cutting, float glass products are obtained.

Compared with other forming methods, float glass has the advantages of being suitable for high-efficiency manufacturing of high-quality flat glass, such as no wave ribs, uniform thickness, flat upper and lower surfaces, and parallel to each other; The scale of the production line is not limited by the forming method, and the energy consumption per unit product is low; High utilization rate of finished products; Easy to manage scientifically and achieve full line mechanization and automation, with high labor productivity; The continuous operation cycle can last for several years, which is conducive to stable production; Suitable conditions can be provided for online production of some new varieties, such as electric float reflective glass, spray coated glass during annealing, cold end surface treatment, etc.

The features of float glass:

The thickness uniformity of float glass is relatively good, and its transparency is also relatively strong. Because it has been treated with tin surface, it is relatively smooth. Under the action of surface tension, it forms a glass with a relatively neat surface, good flatness, and strong optical performance. This type of float glass has particularly good decorative characteristics, such as good transparency, brightness, purity, and bright indoor light. It also has a wide field of vision and is the best preferred material for building doors, windows, and natural lighting materials. It is also one of the most widely used building materials. It can be said that among the various types of building glass, this float glass has the largest application and is one of the most important raw materials for glass deep processing. Ultra white float glass is characterized by its optimal transparency and purity.