Search

FTO and ITO conductive glass, both belong to the category of conductive glass, have their own characteristics.

1.The composition of the coating layer is different.

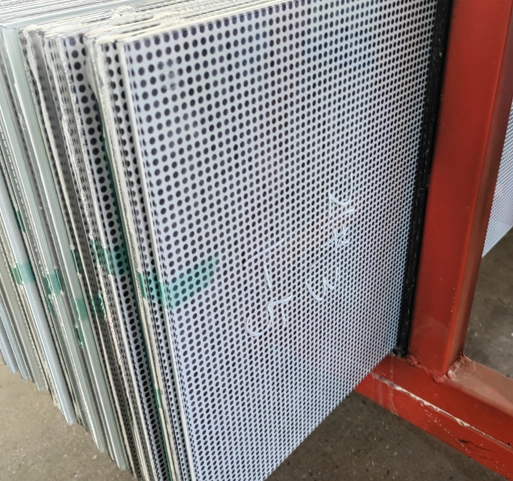

ITO conductive glass refers to glass processed by depositing a layer of indium tin oxide film on a sodium calcium based or silicon boron based substrate glass using magnetron sputtering.

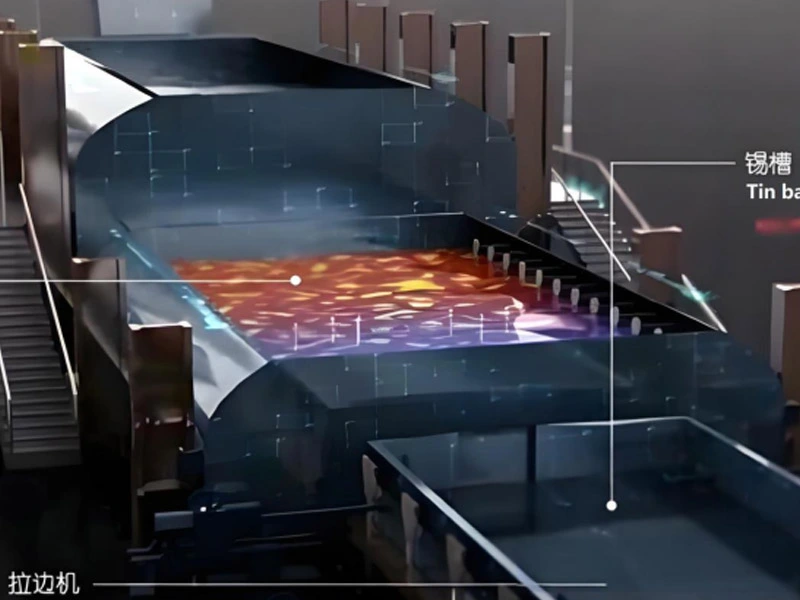

FTO conductive glass refers to fluorine doped tin dioxide conductive glass.

2. In terms of conductivity

ITO glass has better conductivity than FTO glass. If FTO glass is not specially treated, its layered surface has a high potential barrier and is not easy to transfer electrons;

3. In terms of cost

The cost of FTO glass is lower than that of ITO glass.

4.In terms of etching difficulty

The etching process of FTO glass is easier than that of ITO glass.

5.In terms of high temperature resistance

FTO glass has better high temperature resistance than ITO, with the former reaching up to 700 degrees Celsius.

6.After sintering, the resistance change of FTO glass is relatively small, and the sintering effect is better than when using ITO glass as the printing electrode.

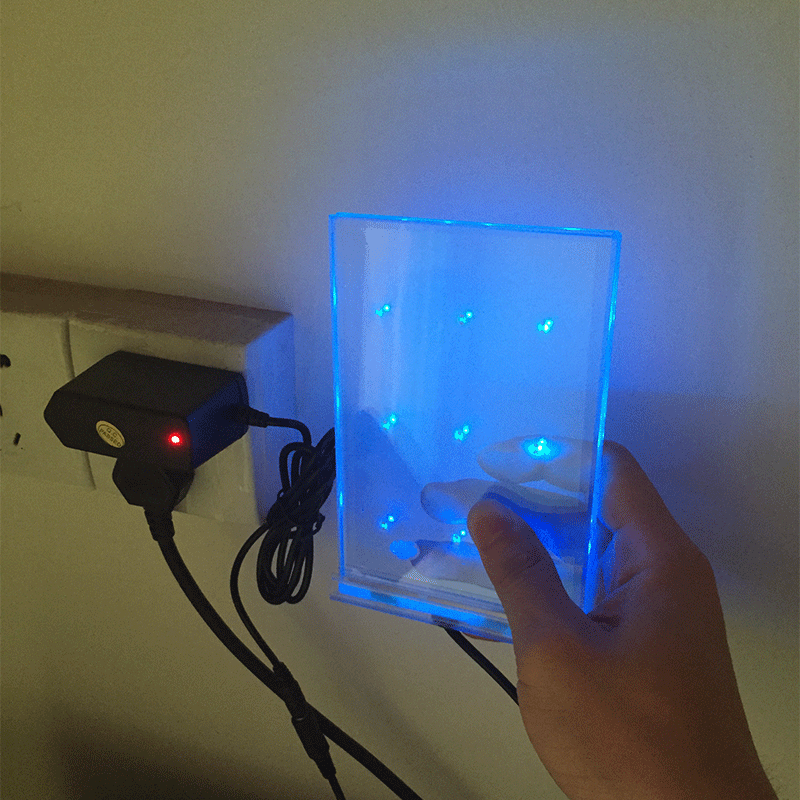

7.In terms of transmittance

FTO glass has a high resistance value and a low transmittance, while ITO glass has a higher transmittance.

Of course, although there are many differences between the two, it must be said that in some fields, FTO glass can be used as a substitute for ITO glass, such as liquid crystal displays, photocatalysis, thin film solar cell substrates, and so on.

This is the first one.

QUICK LINKS

Phone

+86-13505332015Address

Juyuan Road, Wangcun Town, Zibo City, Shandong Province, China